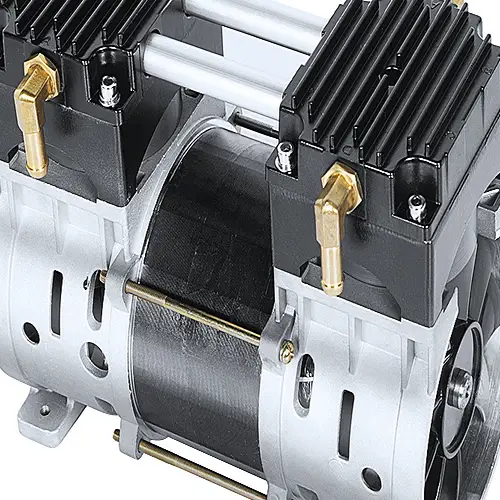

China Custom 50lpm 10 Bar Powerful High Pressure Oil Free Air Compressor for Nitrogen Gas Generator

The China Custom 50lpm 10 Bar Powerful High Pressure Oil Free Air Compressor for Nitrogen Gas Generator is a top-selling product that offers exceptional performance and reliability. Designed with power and efficiency in mind, this air compressor is perfect for various applications.

Product Description

This high-pressure oil-free air compressor is designed to meet the demands of nitrogen gas generators. With a maximum pressure of 10 bar and a flow rate of 50lpm, it provides the power needed for efficient operation. The compact size of 240*113*200 mm and lightweight design of 10.5 kg make it easy to install and transport.

Product Parameter

| ITEM NO | GLE550A-160 |

| Name | Air compressor |

| Packing | 2 Layers Carton Box + Wooden Pallet |

| Weight | 10.5 kg |

| Dimension | 240*113*200 mm |

| Installation size | 89*203 mm (4*M6) |

Technical Specification

The air compressor operates at a voltage of 220V 50Hz and a power of <=800W. It has a restart pressure of 0 bar and a capacitor of 25uF. With a speed of 1370rpm and noise level of ≤68dB(A), it ensures smooth and quiet operation. The temperature range of -5ºC to 40ºC and thermal protector at 135ºC make it suitable for various working environments. It also has insulation class B for added safety.

Other Product Businesses

EVER-POWER GROUP specializes in providing various industrial products to meet different needs. Our wide range of products includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to offering high-quality products, competitive prices, and excellent customer service. We also provide customization services based on drawings and samples.

Frequently Asked Questions (FAQs)

-

Can this air compressor be used for nitrogen gas generation?

Yes, this air compressor is specifically designed for nitrogen gas generators and can provide the necessary pressure and flow rate.

-

What are the dimensions and weight of this air compressor?

This air compressor has dimensions of 240*113*200 mm and weighs 10.5 kg, making it compact and portable.

-

What is the voltage requirement for this air compressor?

This air compressor operates at a voltage of 220V 50Hz, which is suitable for most standard power supplies.

-

Does this air compressor have a thermal protector?

Yes, this air compressor is equipped with a thermal protector that ensures safe operation by preventing overheating.

-

Can I customize this air compressor according to my specific requirements?

Yes, we offer customization services based on drawings and samples. Please contact us to discuss your requirements.

All content on the page comes from the Internet. The content is only used as a reference for product selection. Our products are replacement parts rather than original spare parts. We are not the holders of the original trademark of the content, and our products are only suitable for after-sales replacement parts, not original spare parts. Our replacement parts are designed to perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory or supplier.

Performance Characteristics of Gas Compressor

1. High Efficiency

Gas compressors are designed to operate with high efficiency, ensuring maximum compression and minimal energy loss. By utilizing advanced technology and optimized designs, gas compressors provide efficient compression of gases.

2. Reliable Operation

Gas compressors are known for their reliable operation, ensuring continuous and uninterrupted compression of gases. They are built with robust components and undergo strict quality control measures to ensure their performance and longevity.

3. Versatile Applications

Gas compressors find extensive applications in various industries due to their versatility. They are capable of compressing different types of gases, including natural gas, hydrogen, oxygen, and more. This allows them to be utilized in a wide range of industrial processes.

4. Compact Design

Gas compressors are designed to have a compact footprint, making them suitable for installations where space is limited. Despite their compact size, they offer high compression ratios and deliver exceptional performance.

Types and Characteristics of Gas Compressor

1. Reciprocating Gas Compressor

Reciprocating gas compressors utilize a piston-cylinder mechanism to compress gases. They are known for their high efficiency and ability to handle a wide range of operating conditions. These compressors are ideal for applications that require high compression ratios.

2. Centrifugal Gas Compressor

Centrifugal gas compressors use centrifugal force to compress gases. They are known for their ability to handle large volumes of gas and deliver continuous flow. These compressors are widely used in industries where a constant and high flow rate is required.

3. Screw Gas Compressor

Screw gas compressors employ two interlocking screws to compress gases. They are highly efficient, reliable, and capable of handling varying gas volumes. These compressors are commonly used in applications where a steady flow of compressed gas is needed.

Advantages of Gas Compressor Made of Different Materials

1. Stainless Steel Gas Compressor

Gas compressors made of stainless steel offer excellent resistance to corrosion and are suitable for applications involving corrosive gases. They provide long-term durability and reliability, making them ideal for industries such as chemical processing.

2. Cast Iron Gas Compressor

Gas compressors made of cast iron exhibit high strength and can withstand high pressures. They are commonly used in heavy-duty applications where durability and robustness are essential, such as in the oil and gas industry.

3. Aluminum Gas Compressor

Gas compressors made of aluminum are lightweight and offer good heat transfer properties. They are often used in applications where portability and efficient cooling are required, such as in automotive and aerospace industries.

Application of Gas Compressor

1. Oil and Gas Industry

Gas compressors play a vital role in the oil and gas industry by facilitating the transportation and processing of natural gas, as well as enhancing oil recovery operations.

2. Power Generation and Energy Storage

Gas compressors are used in power plants and energy storage systems to compress gases for efficient energy generation and storage. They help optimize energy conversion processes and contribute to a more sustainable power supply.

3. Medical and Healthcare

In the medical and healthcare sector, gas compressors are used for various applications, including supplying compressed air and gases for medical equipment, supporting respiratory therapy, and facilitating medical gas pipeline systems.

4. Automotive Industry

Gas compressors are utilized in the automotive industry for various purposes, such as compressing air for pneumatic tools, supporting air suspension systems, and enabling efficient fuel delivery in fuel cell vehicles.

5. Chemical Industry

The chemical industry relies on gas compressors for processes such as gas separation, gas recycling, and gas compression during chemical reactions. They ensure efficient operation and contribute to the production of various chemicals.

Future Development Trends and Opportunities

With the increasing demand for energy efficiency and sustainable practices, the gas compressor industry is expected to witness significant advancements. Some future trends and opportunities include:

1. Integration of IoT and Automation

Gas compressors are likely to incorporate IoT (Internet of Things) technologies and automation to enable real-time monitoring, predictive maintenance, and enhanced operational efficiency.

2. Adoption of Renewable Energy Sources

As the world shifts towards renewable energy sources, gas compressors will play a crucial role in compressing gases generated from renewable sources such as biogas, hydrogen, and natural gas.

3. Development of Energy Storage Systems

Gas compressors will contribute to the development of energy storage systems, allowing efficient compression and storage of gases for later use, ensuring a stable energy supply.

4. Emphasis on Environmental Sustainability

Future gas compressors will focus on reducing environmental impact by utilizing eco-friendly refrigerants, improving energy efficiency, and implementing advanced emission control technologies.

How to Choose a Suitable Gas Compressor

When selecting a gas compressor, consider the following aspects:

1. Clear Requirements

Define your specific requirements regarding gas type, flow rate, pressure, and temperature to ensure the chosen compressor meets your needs.

2. Material Selection

Choose a gas compressor made of materials suitable for your application, considering factors such as corrosion resistance, strength, and compatibility with the gases being compressed.

3. Design Optimization

Look for compressors with optimized designs that maximize efficiency, reliability, and ease of maintenance. Consider features such as cooling systems, noise reduction, and safety measures.

4. Suppliers and After-Sales Service

Select reputable suppliers who offer reliable products and comprehensive after-sales service, including maintenance, spare parts availability, and technical support.

5. Cost-Effectiveness

Evaluate the upfront cost, energy consumption, and maintenance expenses to determine the long-term cost-effectiveness of the gas compressor.

6. Quality Control

Ensure the chosen gas compressor undergoes stringent quality control processes, adhering to industry standards and certifications, guaranteeing its performance and reliability.

Author: Dream